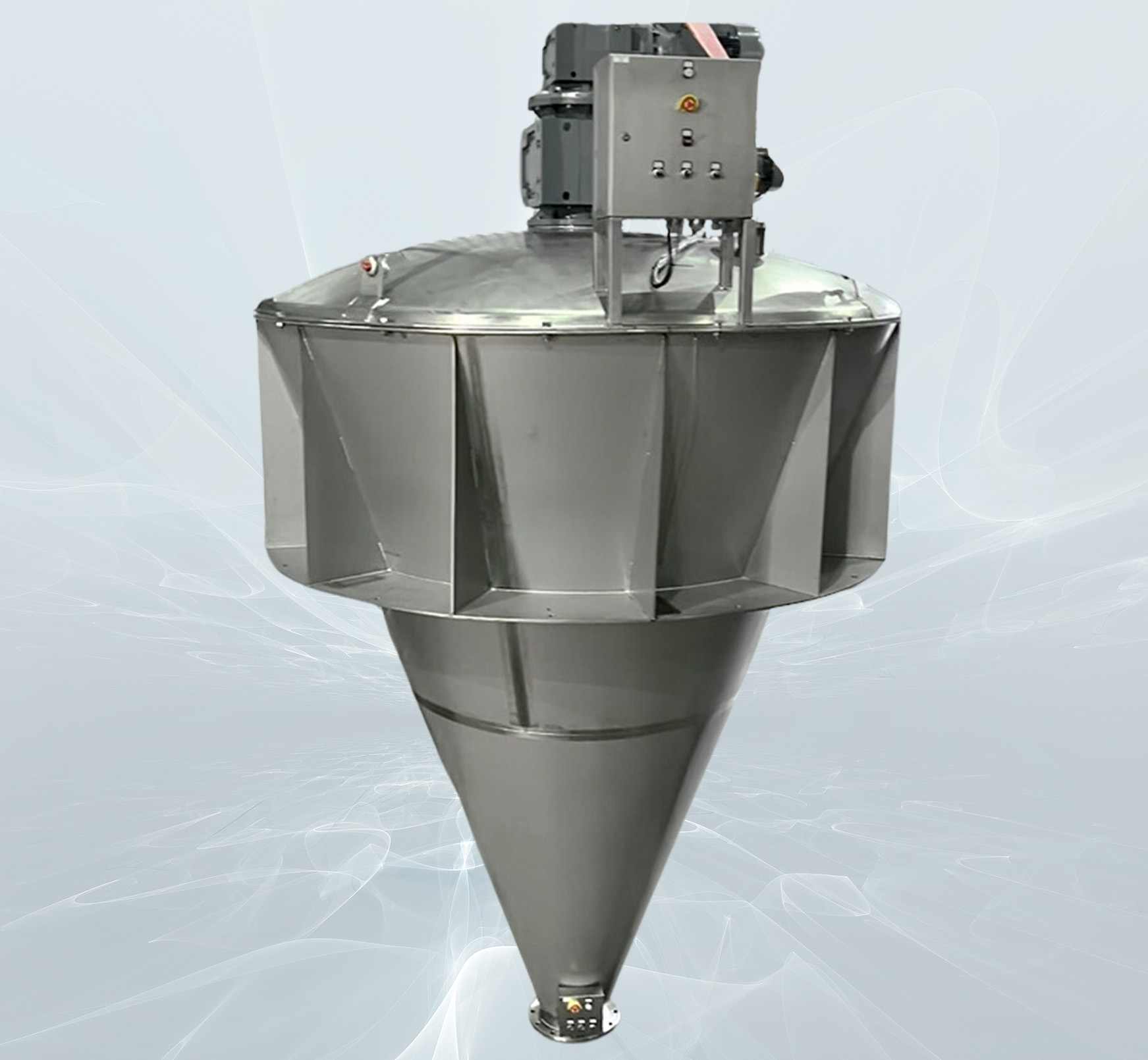

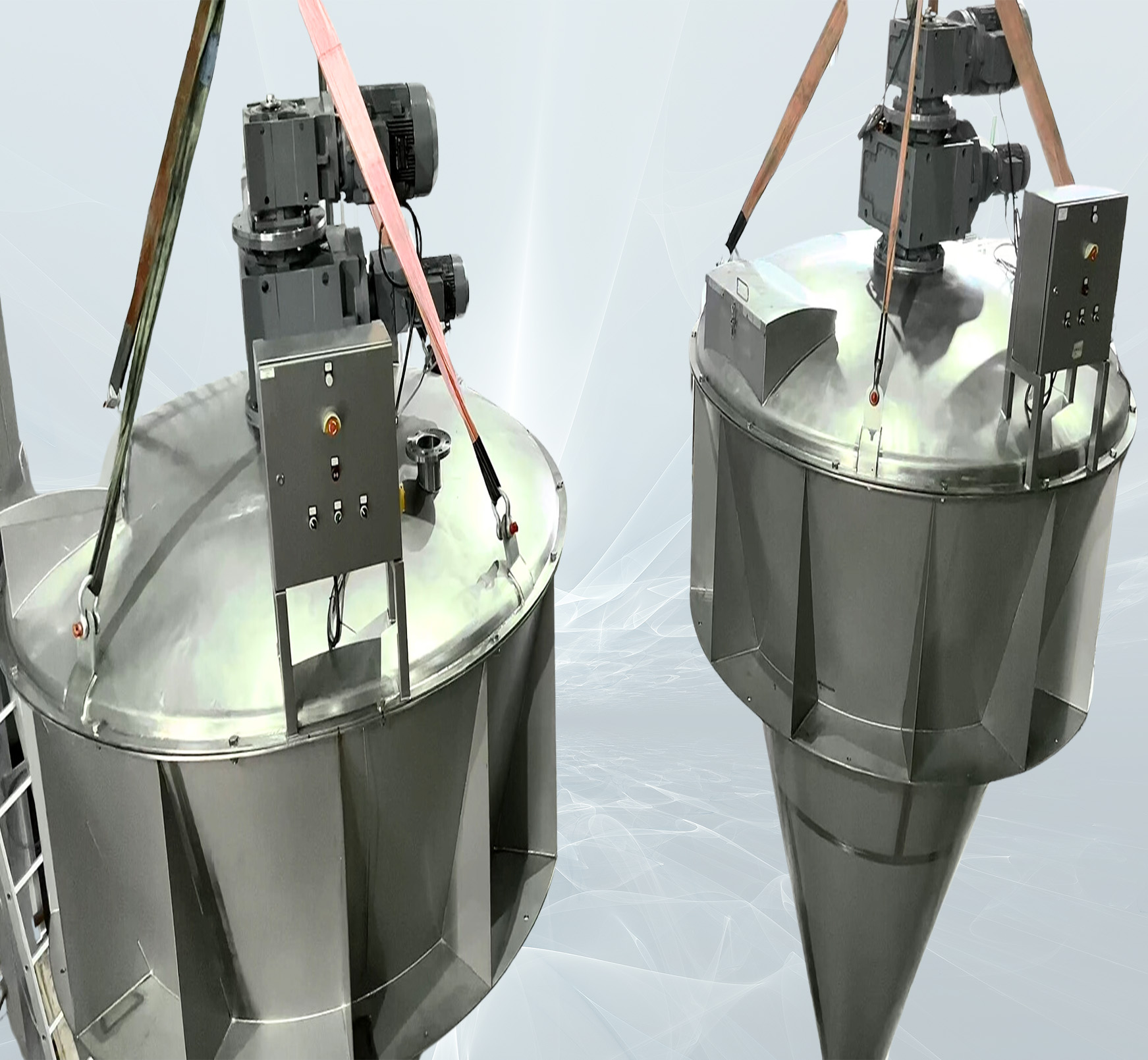

Conical Powder Mixer

ENDULUS KROM Conical Powder Mixers lead the sector in Turkey in terms of engineering, performance, and quality. Since there are no gaskets or bearings in the product area, there is no risk of lubricant contamination. It has deficient energy consumption and low maintenance costs but high mixing, blending, and drying performance. Endülüs Krom is your most reliable solution partner for your powder mixtures.

ADVANTAGES

Let's talk about the advantages of a conical powder mixer (often called a conical screw mixer or conical blender).

Uniform Mixing: Conical mixers are designed to provide a gentle yet effective mixing process. The conical shape provides a rotational motion that ensures thorough powder mixing without causing excessive wear or distortion.

Gentle Handling: The gentle mixing action minimizes the risk of damaging or altering the physical properties of the powdered copper particles. This is particularly beneficial when dealing with fragile or sensitive materials.

Conical mixers are available in a variety of sizes, allowing for scalability. Whether working with a small batch or large quantities of powder, you can choose a suitably sized mixer to meet your production needs.

Versatility: Apart from mixing, conical mixers can also be used for blending, drying, and granulation processes. This versatility makes them valuable equipment in various industries, including pharmaceuticals, food processing, and chemical manufacturing.

Efficient Discharge: Many cone mixers have a bottom discharge mechanism that facilitates efficient and uniform discharge of the blended material. This can streamline the process, and we can offer solutions in an automated system.

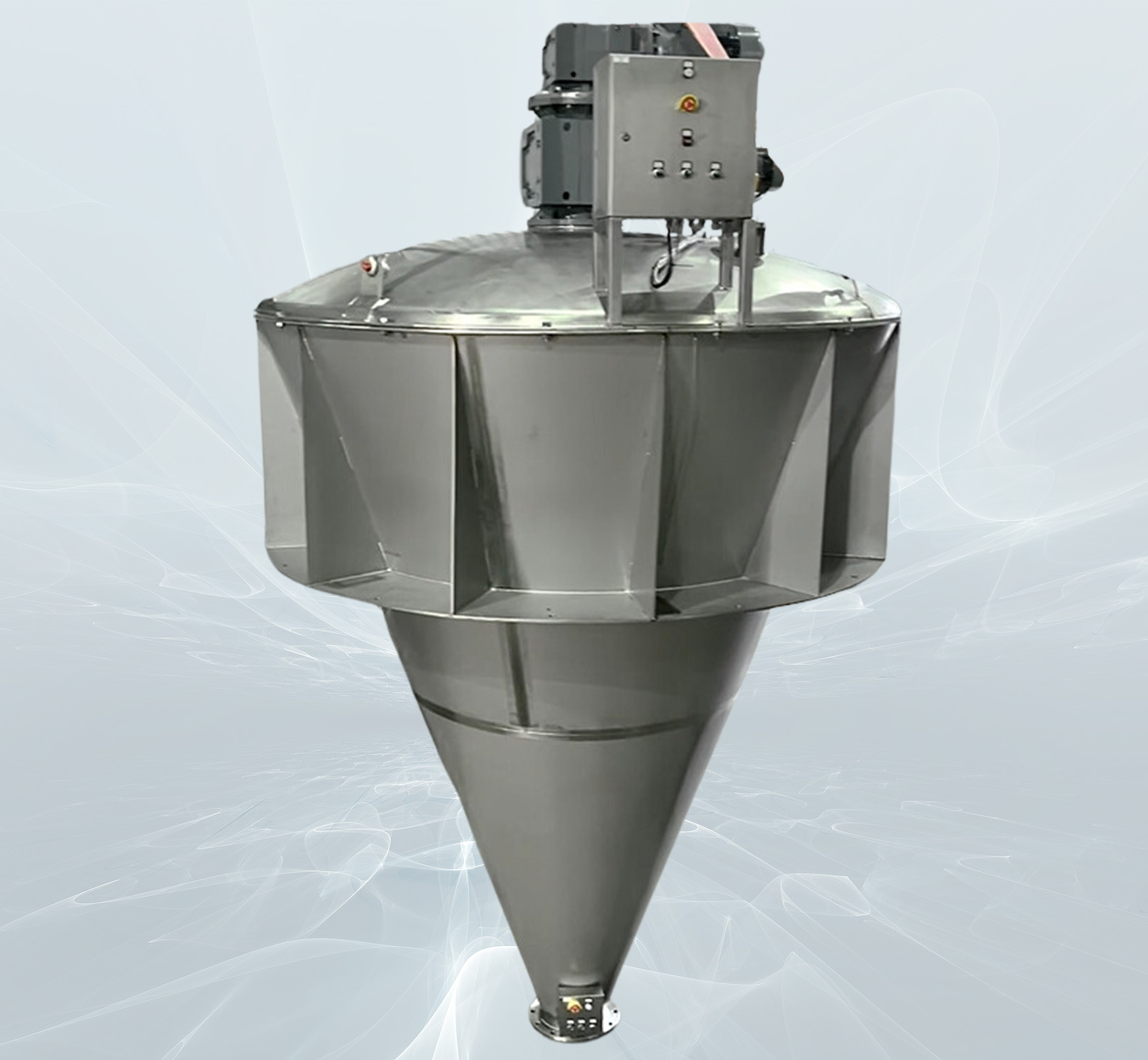

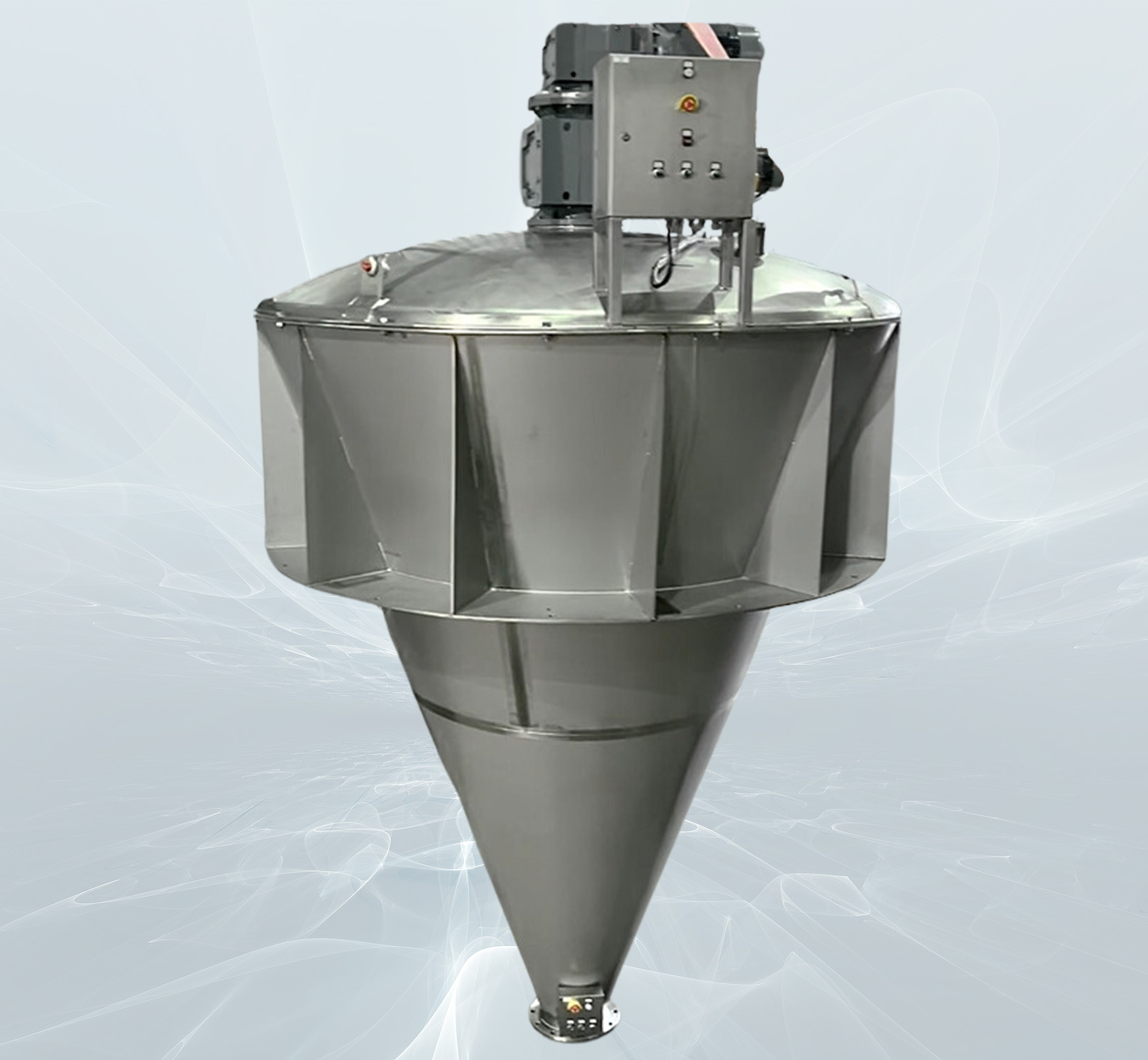

Conical Powder Mixer Photos

Türkçe

Türkçe